DTF the future of Digital Print

Is this the future of digital print?

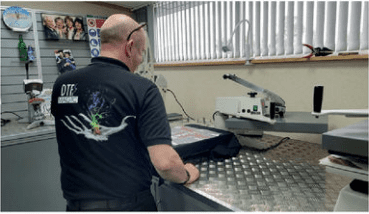

P&P editor Melanie Attlesey speaks with Jim Nicol of TheMagicTouch and Colin Marsh of Resolute DTG to find out more about direct to film printing – the new garment decoration technique that is flooding the market right now.

For my first trip out of the office since the pandemic hit in March 2020. I had to make sure the visit was going to be a good one.

And what better way to spend the day than seeing a new technology in action. Which is pegged as an exciting addition to garment decoration that cannot be ignored.

TheMagicTouch and Resolute DTG have spent the past year beavering away behind the scenes to collaboratively bring to the market the R-Jet Pro DTF printer and automatic finishing unit. This utilises the newest in garment decoration technology.

One of the first things that Jim says to me on arrival at TheMagicTouch in Dunstable is that direct to garment printing is dead. Certainly, a bold claim to make. However, it is a claim that is seconded by Colin when I later speak to him.

As Colin explains: “We have been in the DTG market for the last 12 years and have just watched it fall of a cliff in the last year. Anyone that has come in to view our range of DTG printers have seen the DTF printer sitting in the corner, asked for a demo and are then no longer interested in DTG.”

The reasons for this will become clear later on.

Direct to film printing

Direct to film printing is an alternative process to DTG printing. Using a specially formulated water-based ink, a 60cm wide roll of PET film transfer is printed using two eight channel Epson print heads at a rate of 20sq m per hour. Once printed, a hot-melt adhesive powder is applied to the ink to set the print. The transfer is then heat cured using infrared bulbs ready for storage or instant use. The transfers can be heat applied to garments or other substrates using a traditional heat press at 150˚C for just 15 seconds using medium pressure and warm-cool peel.

TheMagicTouch’s journey to this point began in the summer of 2020 during videocall with Chris Pisani, CEO of TheMagicTouch USA. When talk turned to this new technology that was emerging out of China. Jim explains: “Chris had been watching YouTube videos where Epson printers had been converted to print transfer film. He was amazed by the technology.”

Intrigued by the possibility

Intrigued by the possibility, TheMagicTouch purchased an Epson desktop printer. Nathan Newbury, head of technical, spent three months converting it to make it print transfer films. The first modified printer took an average of 28 minutes to produce an A3 print. It was clear that more work was needed to increase the speed to make it a viable alternative to methods currently on the market. The more Nathan tinkered with the concept the quicker the prints came out of the machine.

Having worked with Resolute DTG on previous projects. Jim approached Colin to start the ball rolling on producing a DTF system built from the ground up. Unbeknown to Jim, Colin had also been intrigued by this technology that was emerging out of China and was already in conversation with his manufacturer about developing a DTF system.

See Link above to continue.